Capability

Contour Optik leads trend innovation and design and manufactures cutting edge products using our state of the art and streamlined quality control.

Contour Optik leads trend innovation and design and manufactures cutting edge products using our state of the art and streamlined quality control.

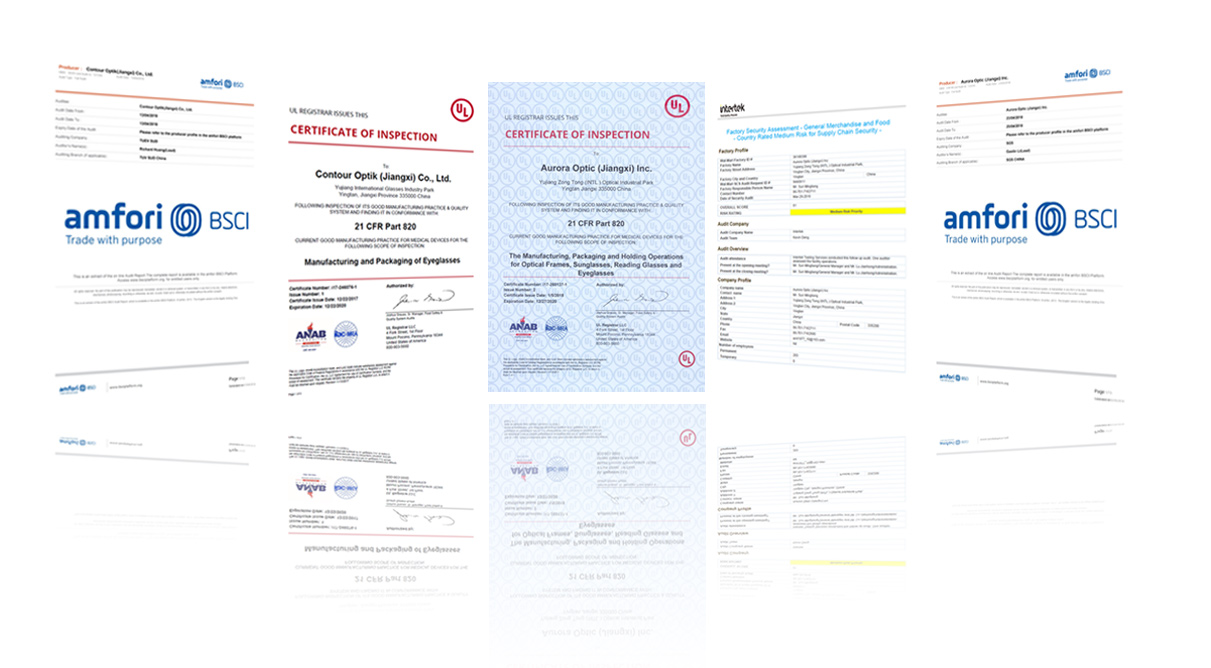

Contour Optik has its own R&D dept. and assembly line in Chiayi, Taiwan, and factories in Yingtan (in Jiangxi), Shenzhen, and Dongguan, in China. The floor area of its glasses industrial park in Yingtan is nearly 25 acres lead consistently manufacture and design optical glasses, sunglasses and reading glasses.

Contour Optik has 40 years of experience in the manufacturing of frames. Our technical advantage is unmatched.

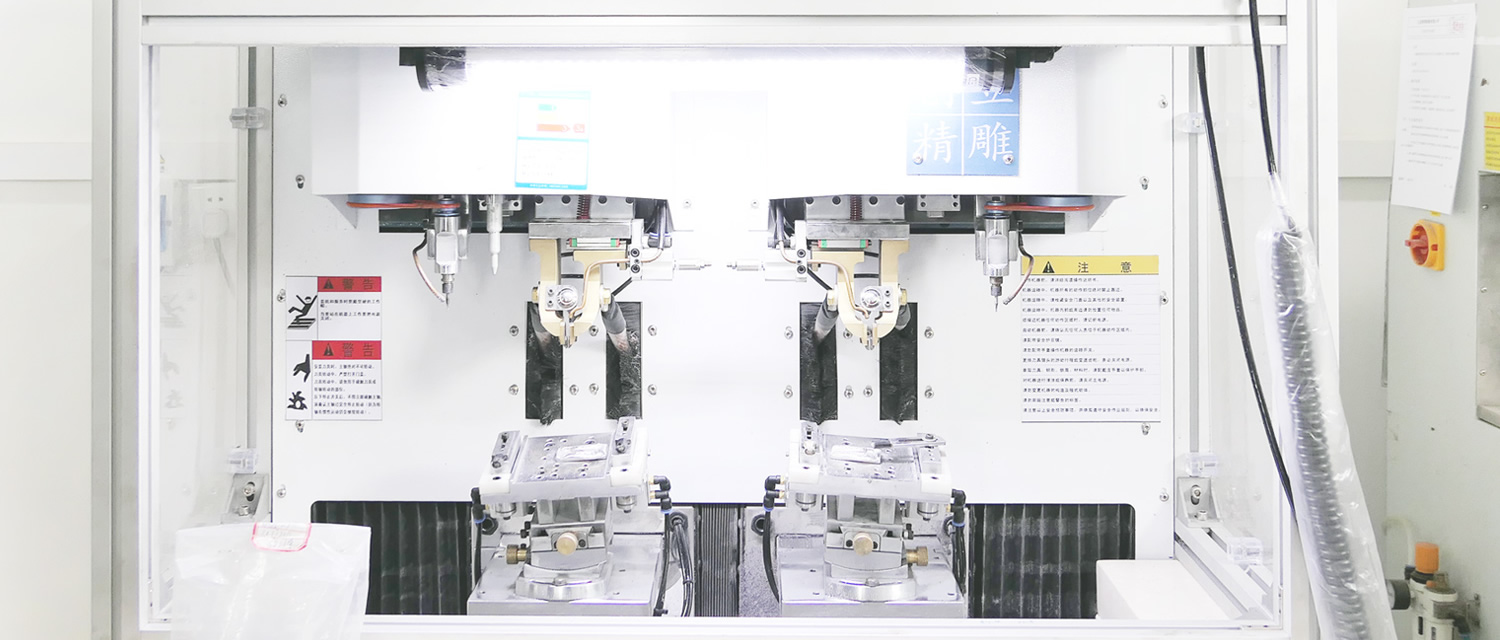

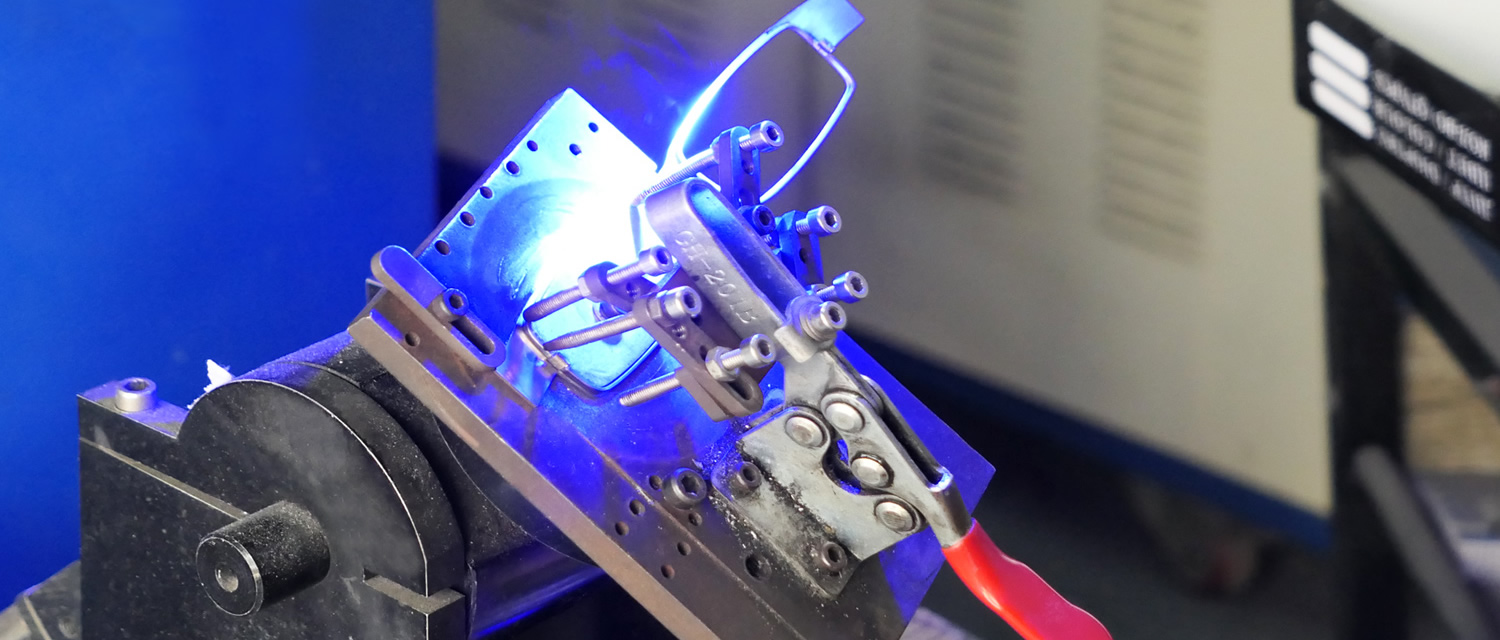

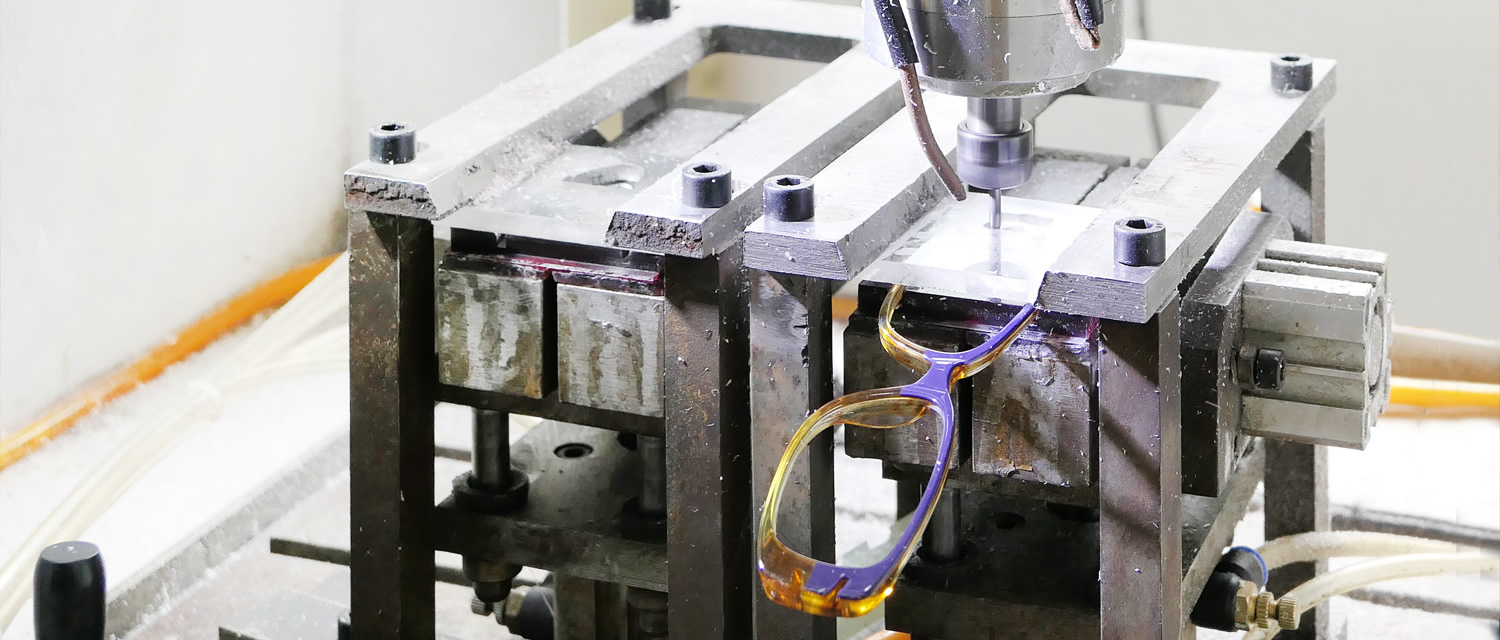

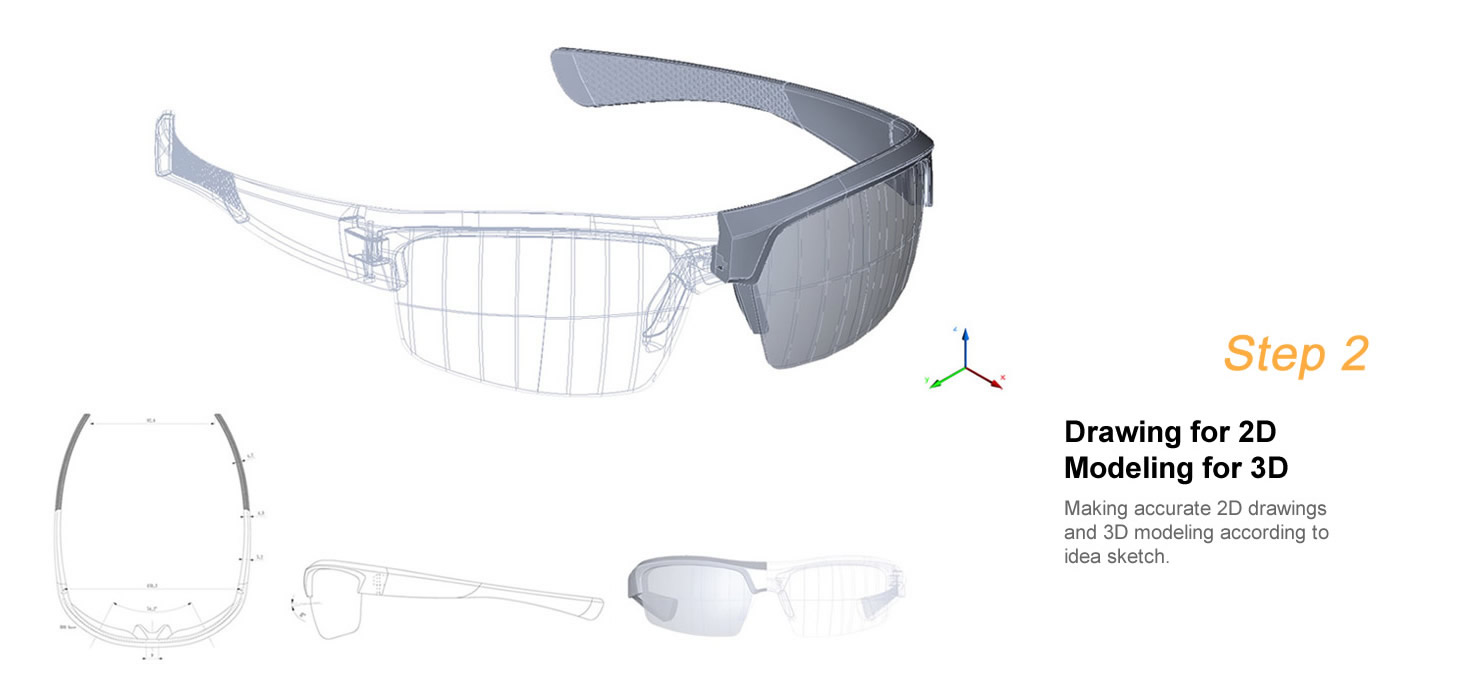

Contour Optik has prolific design experience to produce excellent samples through its own 3D printing which allows customers to do pre-sample for reference. Our factory is equipped with automatic modern CNC processing machinery, plastic injection, spray painting, tooling development and our very own lens factory. The precision technology combines with our detail processing, including decoration metal parts, lens assembly, finished packaging, etc., provide the high executive efficiency and stability to customers.

Contour Optik (Jiangxi) located in YuJiang International Optical Industry Park, Jiangxi, China, is equipped with advanced production equipment.

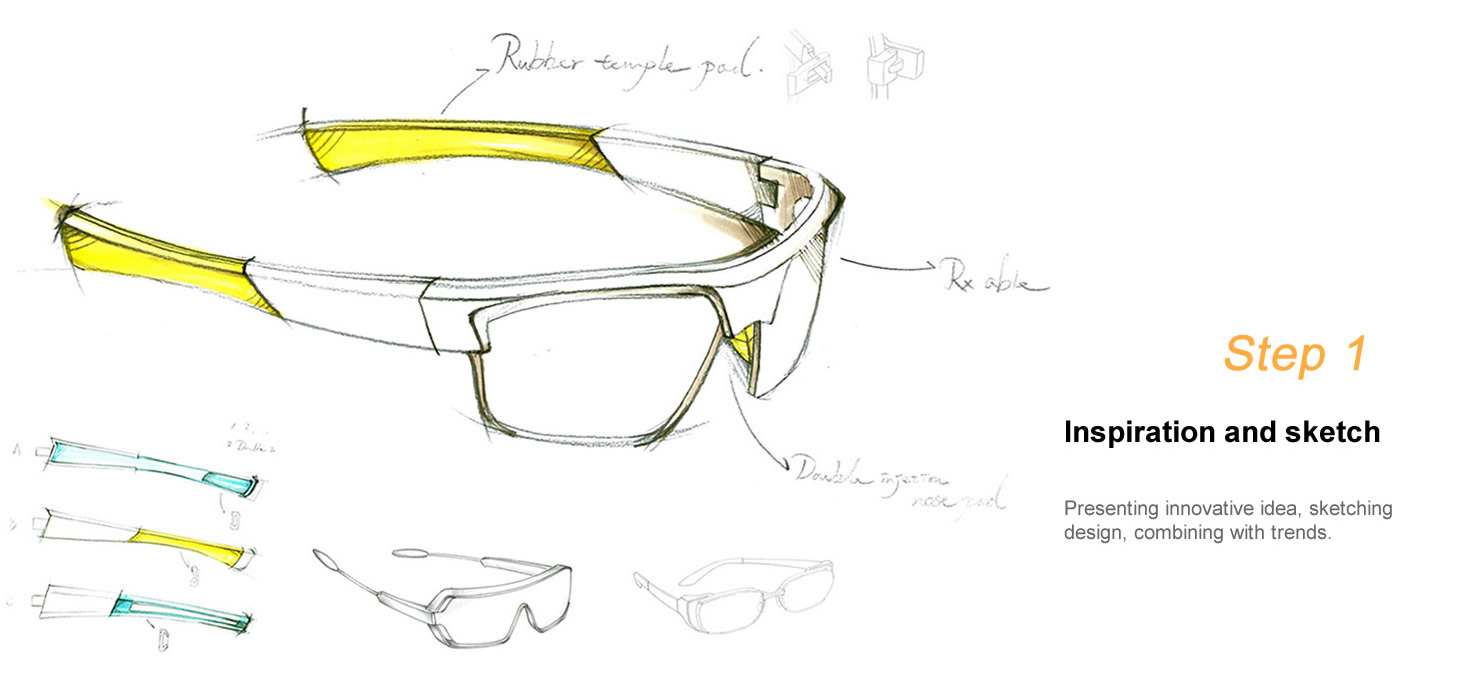

Contour attaches great importance to research, development, and innovation design capabilities. Our R&D team anticipates the latest fashions, designs cutting edge frames, combines excellent processes, and carries out systematic product development based on professional knowledge, marketing information and fashion trends.

Contour Optik with a number of designers and engineers constitute an excellent R&D team. We committee to lead fashion trends in this industry. Starting from customer needs, inspiration providing, to final products completed, Contour Optik's R&D team always walks at the forefront of the times

6 Industrial Fifth Road.Tou Chiau Industrial Park.Chiayi 621 ,Taiwan

TEL:886-5-2207633

mail:jessie@contourop.com

NO.9 Hao Ming Avenu, YuJiang International Optical Industry Park,YingTan City, JiangXi Province, China

TEL:86-701-5861155

mail:terance@contour.cn

NO.6 Building TongFuyu 1st Industrial Park, Tianxin Community,Pingshan District, Shenzhen, GuangDong, China, 518118

TEL:86-755-28611250

mail:gavinyuan@contour-3d.com